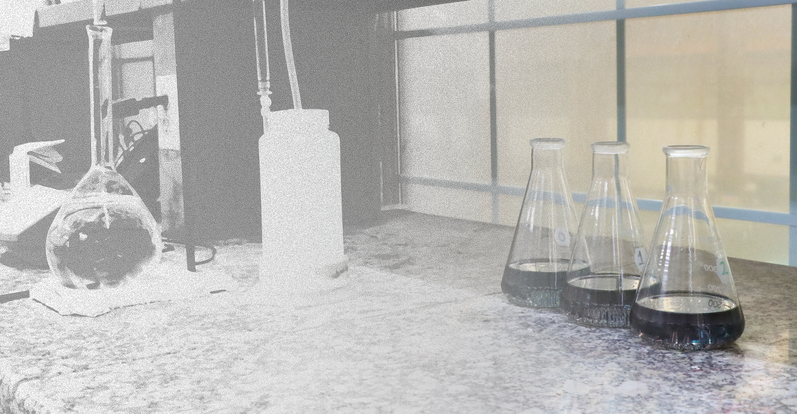

Our laboratory is key to our production processes and quality control

Within this space, essential processes are developed to deliver products with guaranteed quality to our customers. It is here that we ensure that materials meet chemical compositions, resistance levels, and hardness requirements.

What happens in our laboratory?

Raw Materials Analysis:

Tests and analyses are conducted on the raw materials used in aluminum manufacturing to ensure their quality before processing.

Process Control:

Activities such as monitoring and controlling different aluminum production processes are ongoing. Regular tests and analyses are also performed to guarantee compliance with established standards.

Product Quality Control:

Through tests such as resistance, hardness, electrical conductivity, among others, carried out on aluminum samples, we verify if they meet the required standards and specifications for final delivery to the customer.

Research and Development:

To optimize our products, we engage in activities such as researching and developing variables and parameters related to both the process and the product. This helps us generate new proposals and alternatives to create excellent profiles that adapt to the demands of any project.

At Consorcio Industrial Valsa, our priority is to successfully accomplish each stage of the process. Therefore, we ensure that we have the most sophisticated measuring equipment and all the necessary implements to fully comply with current regulations and the required standards in the industries where we distribute value-added aluminum profiles.