An added value is the sum of functionality, efficiency and usefulness that gives additional value to a product.

At Grupo Valsa we offer a range of added values so you can improve your projects.

Die cut:

Die cutting is a mechanical process widely used in metalworking industries to cut, semi-cut, fold and make holes in metal, plastic or cardboard surfaces.

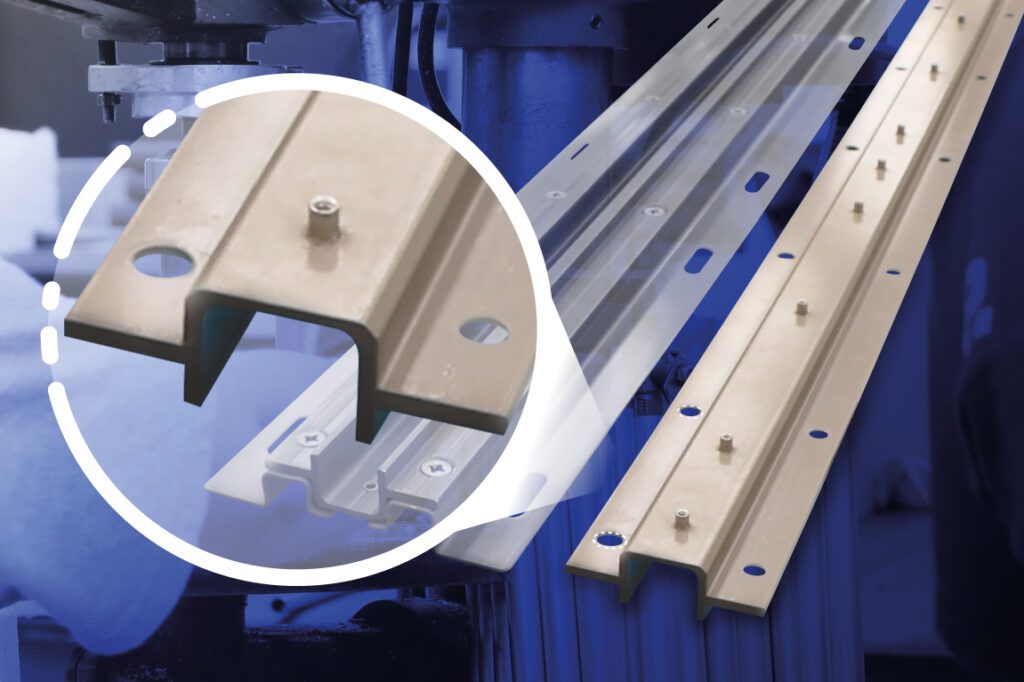

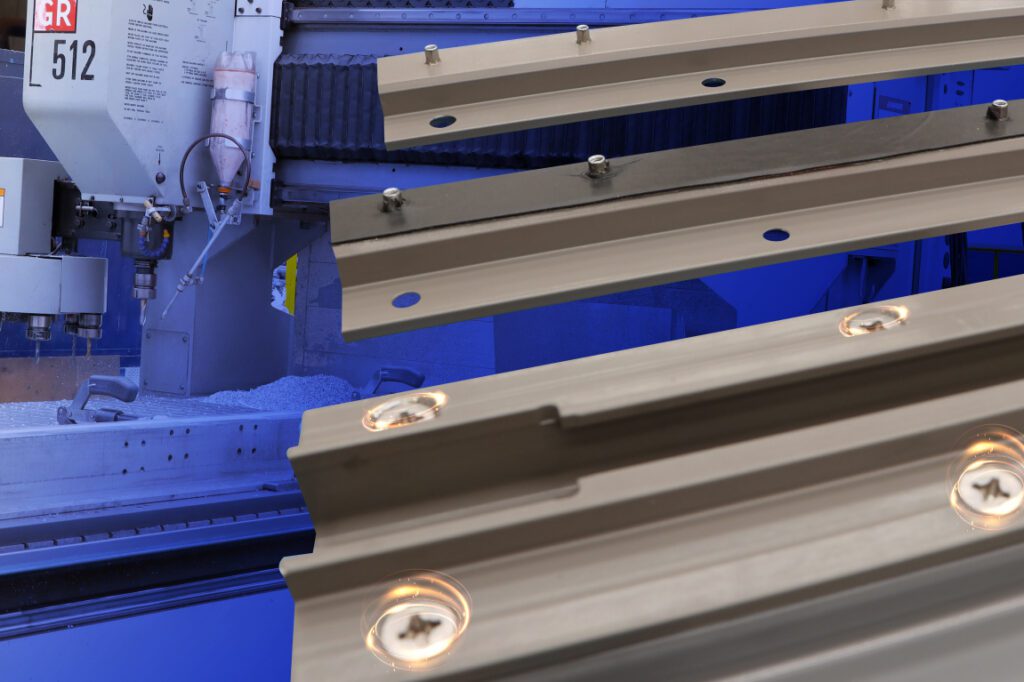

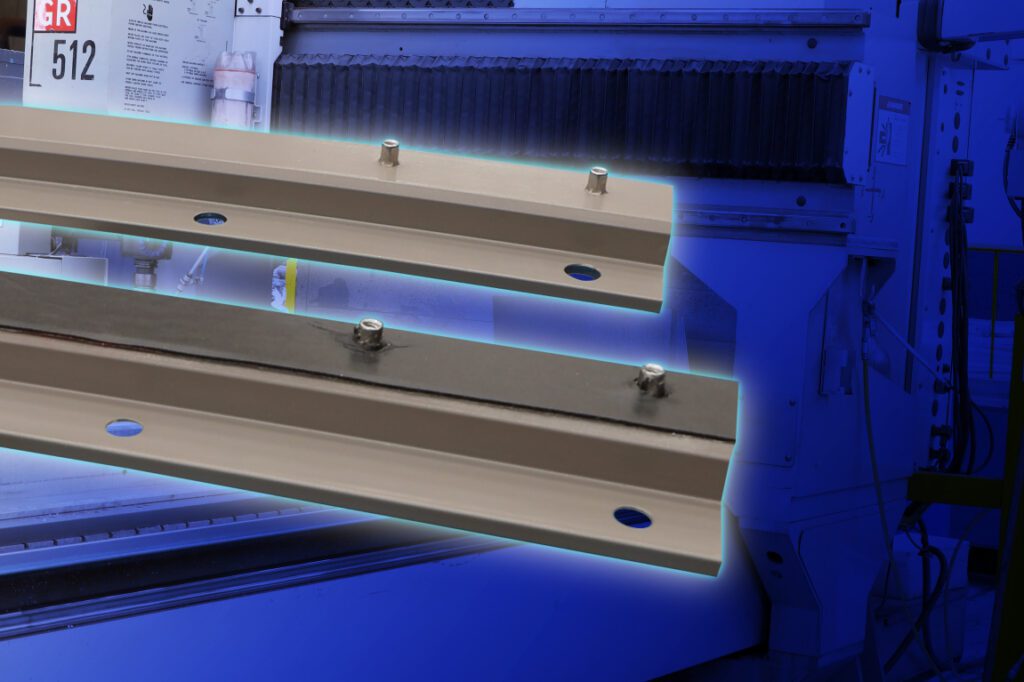

Machining:

It consists of programming the desired cut or figure on the CNC (computer numerical control) to obtain a production of clean pieces, with professional finishes such as precise, straight cuts, slots, curves and more in the aluminum profiles.

Drilling:

It is a method of producing cylindrical holes in a part with metal removal tools.

In addition to short and long hole drilling, it also covers trepanning and subsequent machining such as reaming, boring, threading and broaching.

Soldier:

Welding is considered a process of joining materials in which parts are partially melted through the application of heat and/or pressure.

Many processes use only heat without applying pressure; others combining heat and pressure.

There are welders with and without metal addition.

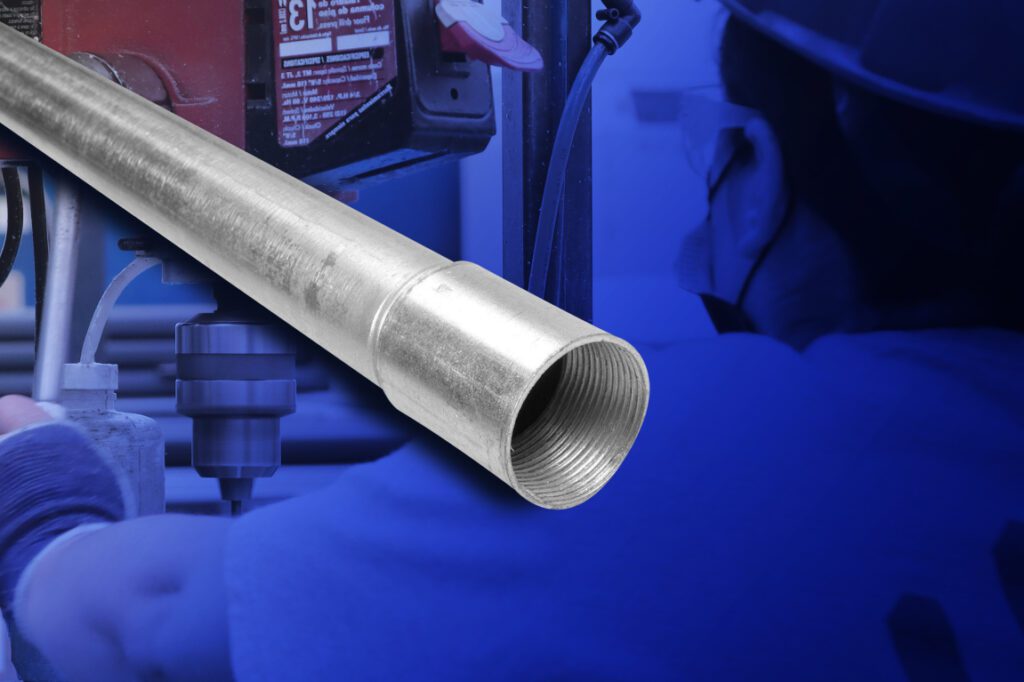

Threading:

The threading process consists of giving a helical shape to a cylindrical surface, whether external (screws) and internal (nuts) or male and female.

The way to do it can be manual or mechanical, depending on the type of thread and its function.

Cut to size:

Cutting processes are used through the mechanical interaction of a tool with a part.

This causes the separation of the material in the contact parts, eliminating material in the form of chips, through toothed discs.

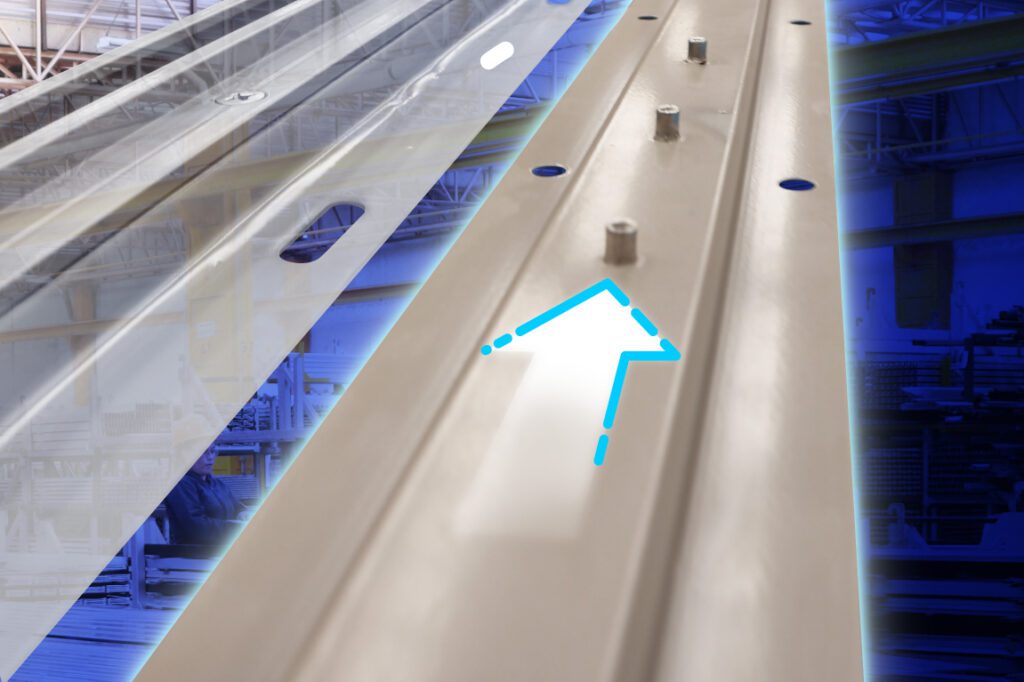

Countersunk:

Mechanical process that consists of creating seats for the countersunk screws so that they do not protrude from the profile surfaces.

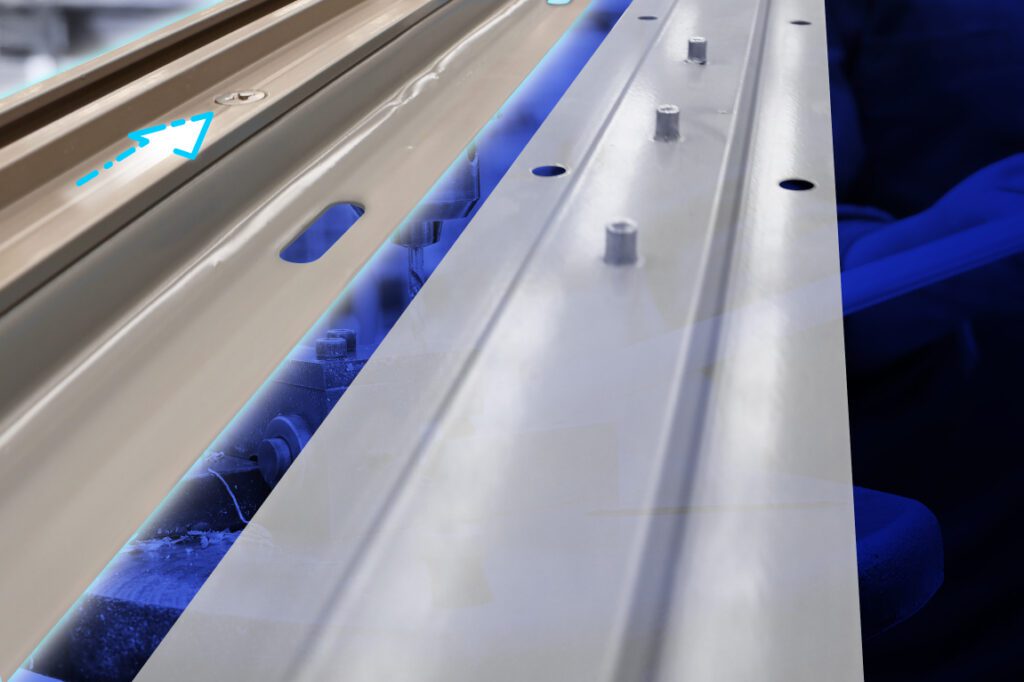

Combined:

Performing more than one value-added process, such as conduit pipes that are performed cutting, countersinking, threading and bending.

Tube Bending:

The bending operation is a manufacturing process that seeks to shape metal profiles.

The bending depends on the diameter of the tube to be bent, as well as its thickness and the material with which it has been extruded.

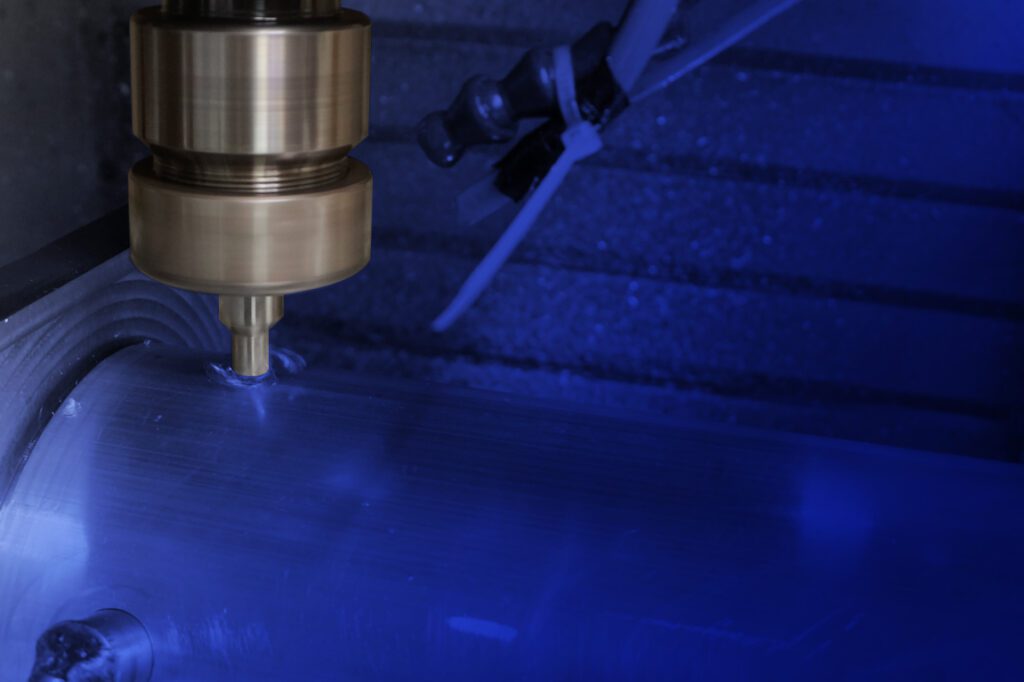

Machining

We can define the machining process as one in which, through a series of lathe operations by removing chips or abrasion, we achieve the molding of a part intended for a specified function.

Such as shape machining, round, countersunk, oval.

CONTACT

Get in touch with our consultants and start changing the way you generate structures with aluminum!