- 14 May, 2024

- Andre Santelices

- 0

Introduction:

The search for lighter, stronger and more efficient materials in the automotive industry has led to the adoption of innovative techniques. In this context, extruded aluminum parts emerge as an essential tool to meet these demands and catalyze progress in the automotive sector.

The Extrusion Process:

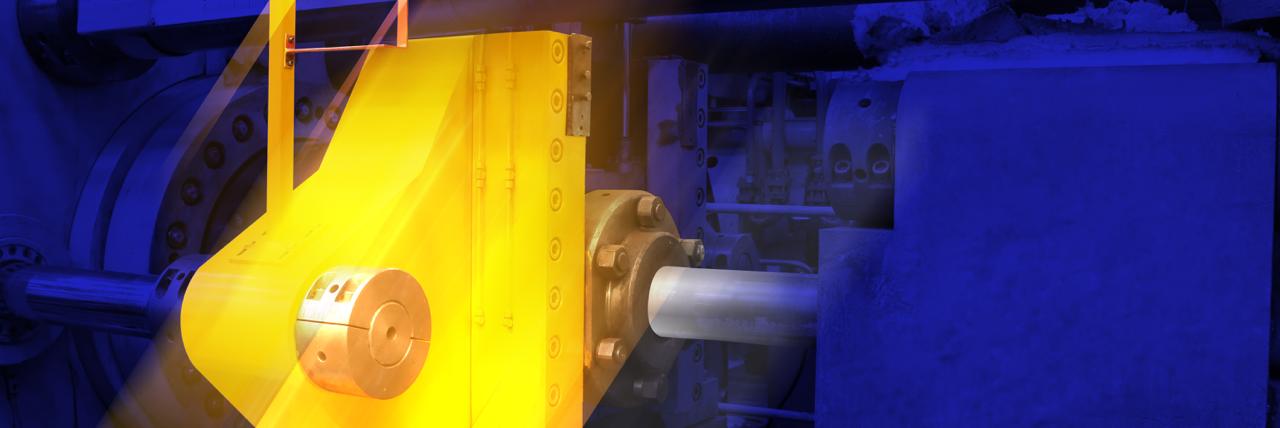

Extrusion is a manufacturing process in which aluminum is pressed through a die with a specific shape. This method allows creating exact profiles and complex shapes, adapting to the needs of the automotive industry with precision and efficiency.

Advantages in the Automotive Industry:

• Weight Reduction: Aluminum, being lighter than steel, contributes significantly to reducing the total weight of the vehicle. This feature not only improves fuel efficiency but also promotes better performance and maneuverability on the road.

• Strength and Durability: Despite its light weight, aluminum exhibits impressive strength and durability, withstanding considerable loads, in addition to resisting adverse environmental conditions when anodized or lacquered, guaranteeing the safety and reliability of vehicles.

• Design: From small profiles to bodywork components, this process allows the creation of personalized parts with specific shapes and sizes, facilitating their integration into different car models.

Applications in the Automotive Industry:

• Structural Components: Used widely in the manufacturing of structural and cosmetic components, including sunroofs, roof racks, and trunk rails. These elements not only reduce the weight of the vehicle, but also improve its strength and structural rigidity.

• Suspension Systems: Control arms and struts made of aluminum are used in suspension systems to reduce unsprung mass and improve vehicle response and handling.

• Transmission Systems: Extruded aluminum components, such as transmission cases, are used to reduce the load on the powertrain and improve overall vehicle efficiency.

Conclusion:

Profile extrusion in the automotive sector is playing a vital role in the transformation of the industry. Its ability to offer a unique combination of light weight, strength and design flexibility makes it an indispensable tool for the creation of more efficient vehicles, elegant and advanced.

Join the revolution! Discover how profile extrusion is reshaping the automotive industry. Experience the power of lightweight, strength, and design flexibility for yourself. Embrace innovation and drive towards a future of more efficient, elegant, and advanced vehicles today!

CONTACT

Get in touch with our consultants and start changing the way you generate structures with aluminum!